16 Bolt Torque Pattern

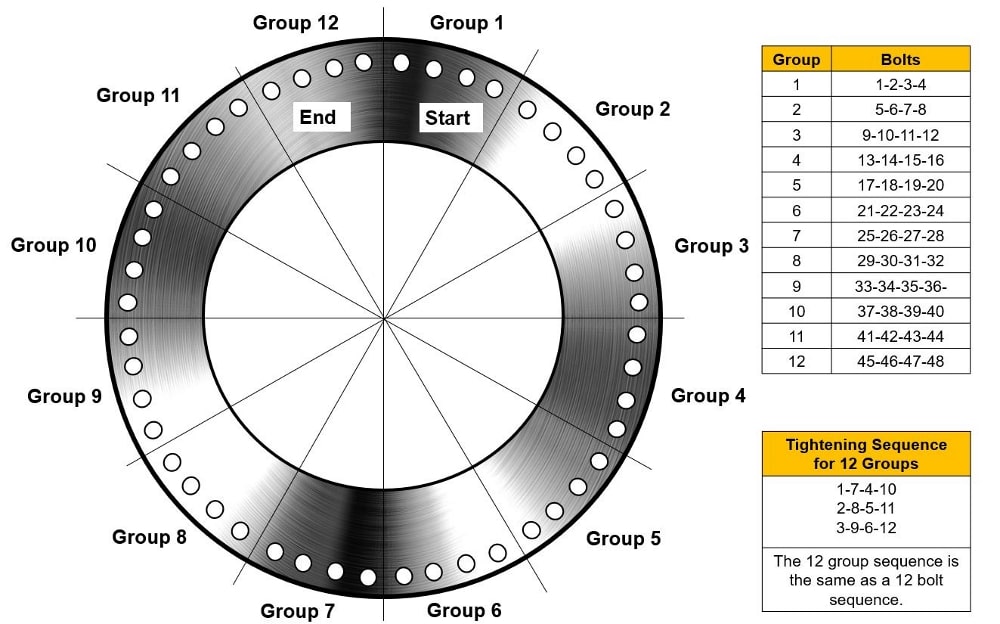

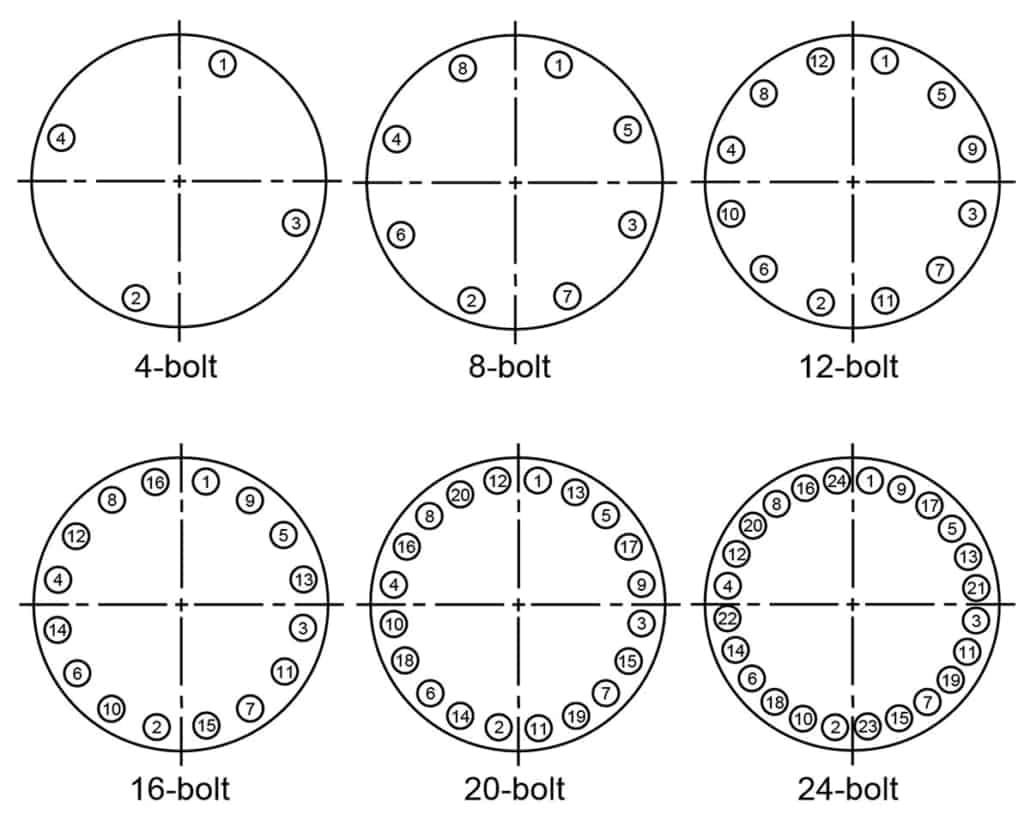

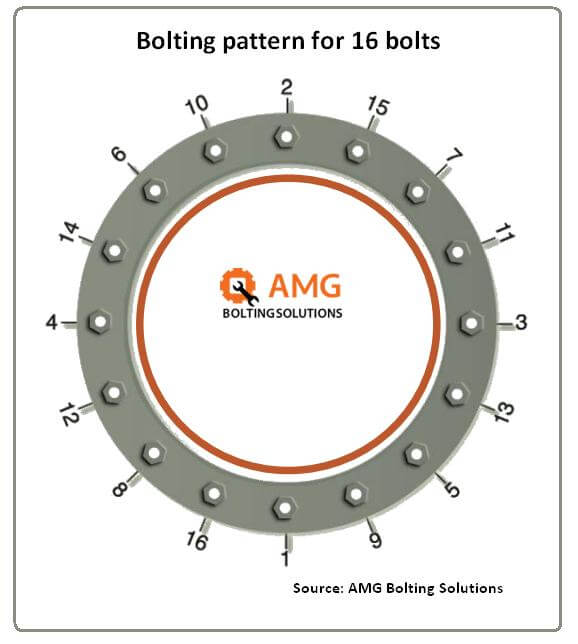

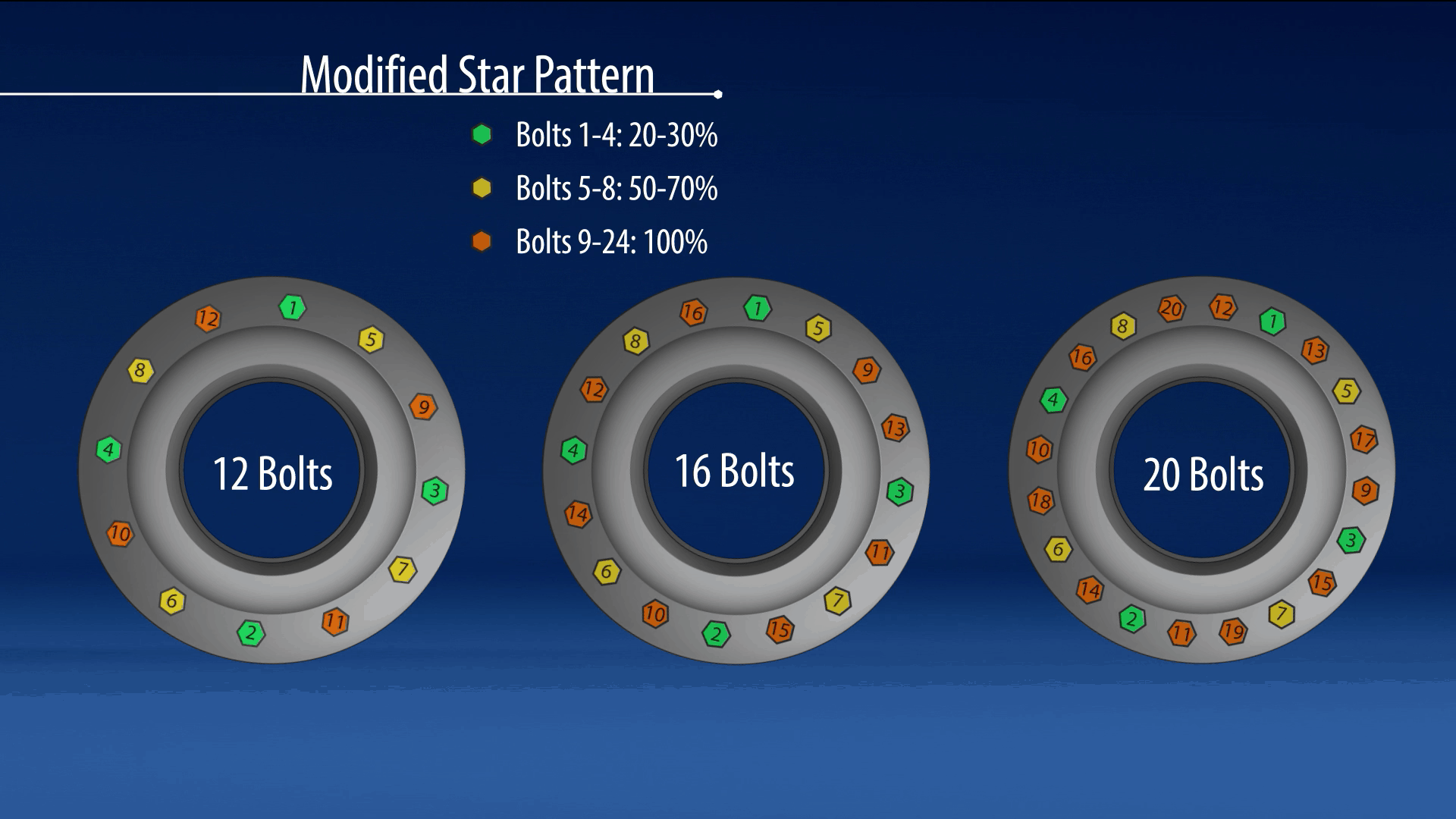

16 Bolt Torque Pattern - Web bolt pattern and torque specification. Web to calculate the torque required to tighten a bolt: Torque head bolts in sequence shown to 220 in. Uip supplies gaskets of all types & sizes for many industrial applications. In this article, you will learn about the torque sequence of pipe flanges. East pompano beach, fl 33060. Web ansi 150# flanges ansi 300# flanges ansi 600# flanges. On critical joints, a tightening pattern that tightens the bolts more. Web flange joints require proper tightening to avoid leakage. Web flange bolt torque patterns. Grade 2, 5, and 8 values are for slightly lubricated bolts. The prevailing torque lock nut clamp loads are listed at 75% of the proof loads specified for the appropriate grade bolt: Start the tightening procedure by lubricating the nuts and bolts. Web flange bolt torque patterns. Garlock sealing technologies an enpro industries company. Web to calculate the torque required to tighten a bolt: Web flange bolt torque sequence www.hswhite.com | 954.785.6760 | sales@hswhite.com 1350 south dixie hwy. Web bolt pattern and torque specification. Web place cylinder head gasket over alignment dowels on cylinder block. Torque head bolts in sequence shown to 220 in. Web this pattern follows a square quadrant sequence and is used on flanges with 16 bolts or more. Web bolt torque chart showing suggested torque values and corresponding bolt clamping forces for various sizes and specifications of fasteners. The following charts indicate the approximate bolt torque required to seal flanged joints against internal pressure. Uip supplies gaskets of all types. Grade 2, 5 and 8 values are for plated bolts. 1, 9, 5, 13, 3, 11, 7, 15, 2, 10, 6, 14, 4, 12, 8, 16. Then hand tighten till they are snug against the flanges. Web flange joints require proper tightening to avoid leakage. The torques given are based on using a. In this article, you will learn about the torque sequence of pipe flanges. Web ansi 150# flanges ansi 300# flanges ansi 600# flanges. Grade 2, 5 and 8 values are for plated bolts. Web control the torque applied, the bolting pattern and the tightening sequence to avoid leaks. Web to calculate the torque required to tighten a bolt: Web ansi 150# flanges ansi 300# flanges ansi 600# flanges. Garlock sealing technologies an enpro industries company. Web ses 75% of the yield strength. Web a complete torque tightening sequence with charts for class 150 to 2500 flanges. Web us recommended bolt torque. Web flange joints require proper tightening to avoid leakage. Recommended torque values lubricated stud bolts w/0.15 friction value. Web bolt pattern and torque specification. Web flange bolt torque sequence www.hswhite.com | 954.785.6760 | sales@hswhite.com 1350 south dixie hwy. Then hand tighten till they are snug against the flanges. Web garlock sealing technologies an enpro industries company. Web flange bolt torque sequence www.hswhite.com | 954.785.6760 | sales@hswhite.com 1350 south dixie hwy. Grade 2, 5, and 8 values are for slightly lubricated bolts. Web bolt torque chart showing suggested torque values and corresponding bolt clamping forces for various sizes and specifications of fasteners. The prevailing torque lock nut clamp loads. Uip supplies gaskets of all types & sizes for many industrial applications. Web flange joints require proper tightening to avoid leakage. Web place cylinder head gasket over alignment dowels on cylinder block. The prevailing torque lock nut clamp loads are listed at 75% of the proof loads specified for the appropriate grade bolt: Grade 2, 5, and 8 values are. Grade 2, 5, and 8 values are for. Web us recommended bolt torque. Web bolt pattern and torque specification. Web to calculate the torque required to tighten a bolt: Web flange bolt torque patterns. Web bolt pattern and torque specification. Then install and finger tighten all fasteners. Grade 2, 5, and 8 values are for slightly lubricated bolts. Web flange bolt torque sequence www.hswhite.com | 954.785.6760 | sales@hswhite.com 1350 south dixie hwy. Number the bolts/flange according to the. In this article, you will learn about the torque sequence of pipe flanges. Web a complete torque tightening sequence with charts for class 150 to 2500 flanges. Web garlock sealing technologies an enpro industries company. 1, 9, 5, 13, 3, 11, 7, 15, 2, 10, 6, 14, 4, 12, 8, 16. Web to calculate the torque required to tighten a. Web us recommended bolt torque. Grade 2, 5, and 8 values are for. Bolt tightening sequence, or torque sequence, is defined in the torque tightening procedure. Web flange joints require proper tightening to avoid leakage. The advantage of this is after 4 bolts are completed it is always. Web to calculate the torque required to tighten a bolt: Web flange bolt torque patterns. Then hand tighten till they are snug against the flanges. Number the bolts/flange according to the. Web ses 75% of the yield strength. Web a complete torque tightening sequence with charts for class 150 to 2500 flanges. Grade 2, 5, and 8 values are for slightly lubricated bolts. The prevailing torque lock nut clamp loads are listed at 75% of the proof loads specified for the appropriate grade bolt: On critical joints, a tightening pattern that tightens the bolts more. Recommended torque values lubricated stud bolts w/0.15 friction value. Web control the torque applied, the bolting pattern and the tightening sequence to avoid leaks.16 Bolt

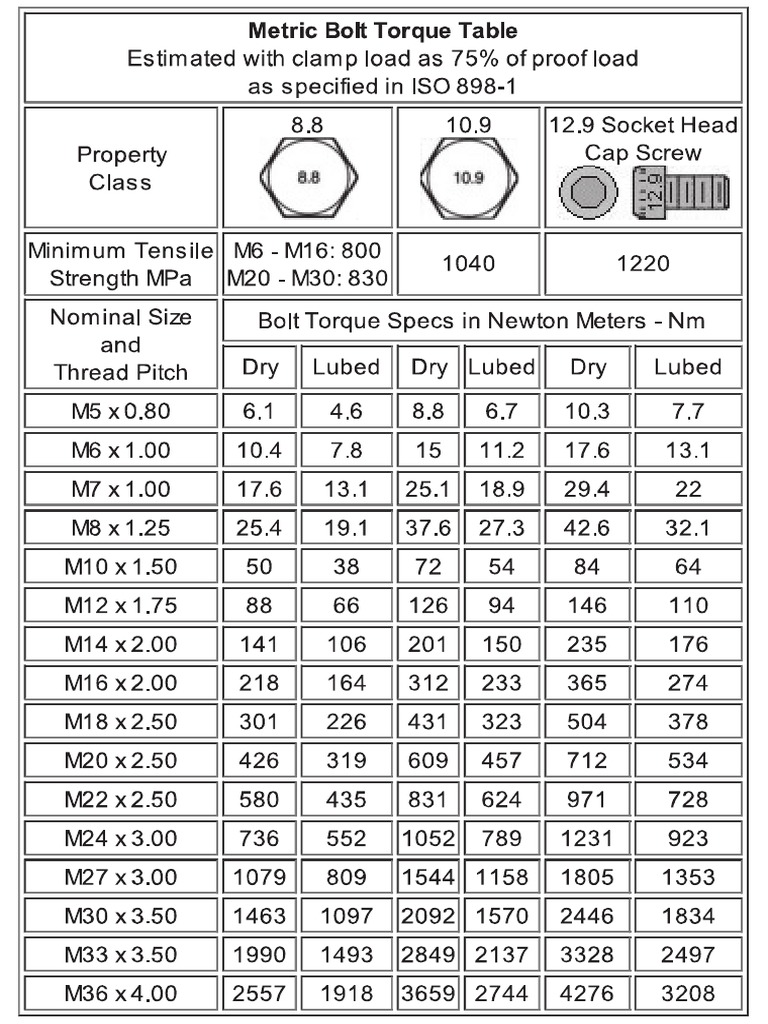

Printable Bolt Torque Chart

Flange Bolt Torque Sequence UIP International Premium, 41 OFF

Flange Bolt Torque Sequence UIP International Premium Industrial

16 Bolt Torque Pattern

Torque Charts Industrial Bolting and Torque Tools

AMG Bolting offer free guidelines for tightening bolt circles, up to 96

Flange Bolt Torque Sequence and Torque Table A Complete Bolt

Pipe Flange Bolt Torque Chart

Bolt Tightening Sequence and Restrictions Hex Technology

The Following Charts Indicate The Approximate Bolt Torque Required To Seal Flanged Joints Against Internal Pressure.

Start The Tightening Procedure By Lubricating The Nuts And Bolts.

Determine Bolt Size — Find The Diameter And Thread Pitch Of The Bolt.

Grade 2, 5 And 8 Values Are For Plated Bolts.

Related Post: